The cement industry stands at a pivotal juncture, facing the monumental task of achieving net-zero emissions by 2050. This ambitious goal necessitates an unprecedented technical transformation, heralding what could be the most significant evolution in the industry's history. Immediate, decisive actions within plants and corporations are now more urgent than ever, as we strive to align with global sustainability targets.

The Critical Need for Process Models

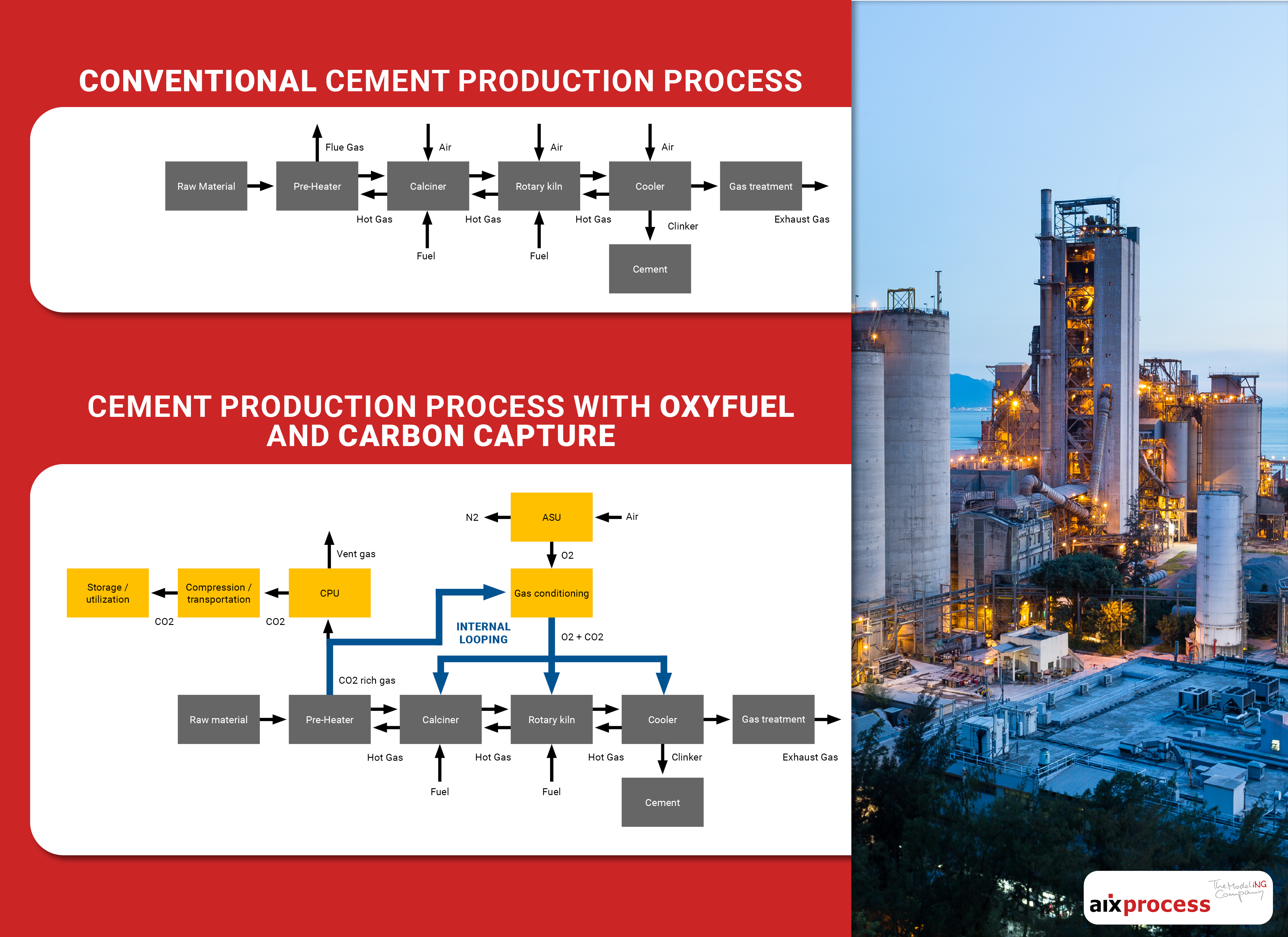

As we delve into future-oriented process concepts like carbon capture and implement Oxyfuel conditions in the pyro-process, the cement industry encounters a complex new landscape. This includes enhanced gas recirculation and the formation of internal loops, which challenge traditional design rules and complicate the reliable estimation of operational and investment costs.

The transition away from fossil fuels not only necessitates changes in the established process equipment but also introduces additional layers of complexity to process control. This shift from a linear to a looping process framework underscores the indispensable need for process models in the cement industry, essential for both concept development and process design.

Transformative Benefits of Process Models

Adopting process models enables the industry to embrace innovative process concepts and navigate the intricate maze of new operational conditions with confidence. These models serve as a cornerstone for making informed, forward-looking decisions that are crucial for the industry’s adaptation to sustainability demands. Here’s how process models are transforming the landscape:

-

Enhanced Precision: Process models allow for the accurate prediction of material and energy flows, taking into account the internal loops that are critical for the technical design of the process and its equipment.

-

Informed Decision-making: With model-based predictions, initial cost estimations can be significantly refined, providing a more reliable foundation for future investment decisions. This is vital for planning and executing the strategic shifts required for the industry to meet its net-zero objectives.

Looking Ahead

The adoption of process models in the cement industry represents a crucial step towards not just meeting the net-zero emissions target but also towards redefining the industry's approach to sustainability and innovation. By leveraging the power of process modeling, the industry can unlock new potentials in process efficiency, environmental compliance, and ultimately, sustainable growth.

As the cement industry ventures into this uncharted territory, the role of process models becomes increasingly central to its success. These tools not only offer the precision and foresight needed to navigate the complexities of modern cement production but also symbolize the industry's commitment to a cleaner, more sustainable future.

Join the Conversation

We're interested in hearing your thoughts. How do you see process models shaping the future of the cement industry? Share your insights and join the discussion on the path to net-zero emissions.