Delving Deeper: The Unconventional Path of Quenching in Inline Scrubber Modeling

In the intricate world of Inline scrubber modeling, the standard practice often involves a straightforward approach—overlooking the detailed simulation of water droplets once they have successfully captured dust particles and collided with the scrubber's wall. This method is primarily driven by the need to enhance computational efficiency, a cornerstone for achieving fast and effective modeling results. However, in a recent project highlighted through our video, we embarked on a less traveled road. The question arises: why adopt this unconventional methodology?

The Standard Approach: A Matter of Temperature Equilibrium

Typically, within a Inline scrubber, water and gas are kept at a uniform temperature, a condition that simplifies the modeling process but might not accurately reflect all operational scenarios. This conventional setup works well under standard conditions, but it doesn't account for special applications where water's role transcends mere cleaning.

Introducing Quenching: A Special Use Case

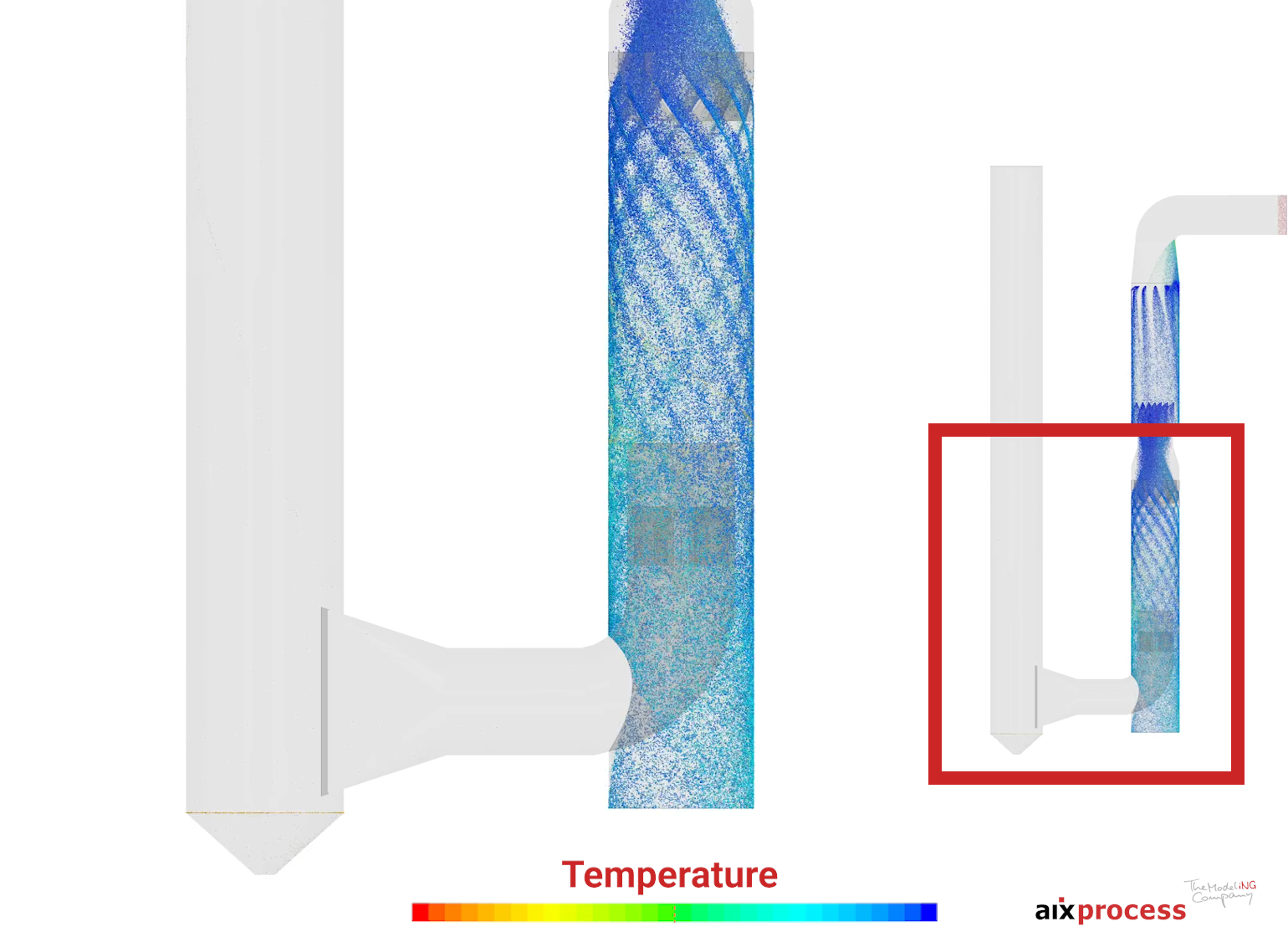

For this specific project with Dieffenbacher, the role of water was elevated from a mere cleaning agent to a quenching medium. This pivotal shift required us to rethink our modeling strategy. By implementing a series of targeted adjustments, we reintegrated the complex dynamics of agglomerated water/wood dust particles back into our computational analysis. This strategic move enabled us to closely examine the thermal dynamics at play—particularly, the cooling effect exerted by water as it interacts with the scrubber wall and the hot gas phase.

Observing Thermal Impacts: Beyond Standard Modeling

This detailed observation revealed insights into the actual cooling effects of water on the gas phase—data that is often overlooked in traditional Inline scrubber models. By accurately simulating this interaction, we were able to provide a more comprehensive understanding of how quenching can enhance the scrubber's performance, especially in terms of thermal management.

The Result: Enhanced Understanding and Application

This analytical journey not only showcased the specific cooling benefits of using water as a quench but also highlighted the importance of flexibility in modeling practices. By stepping outside the norm, we were able to uncover valuable information that could lead to more efficient and effective scrubber designs in the future