Last month's calendar focused on precision fermentation in biotechnology and how CFD can help in upscaling fermentation reactors.

The Scale-Up Challenge in Precision Fermentation: Scaling up in precision fermentation is a complex task that involves transitioning from small-scale laboratory experiments to large-scale industrial processes. This shift is not just about increasing the size of the equipment; it's about ensuring that the process remains efficient, effective, and predictable at a larger scale. This is where the challenge lies: How can one ensure that the scaled-up process mirrors the precision and efficiency of its smaller counterpart?

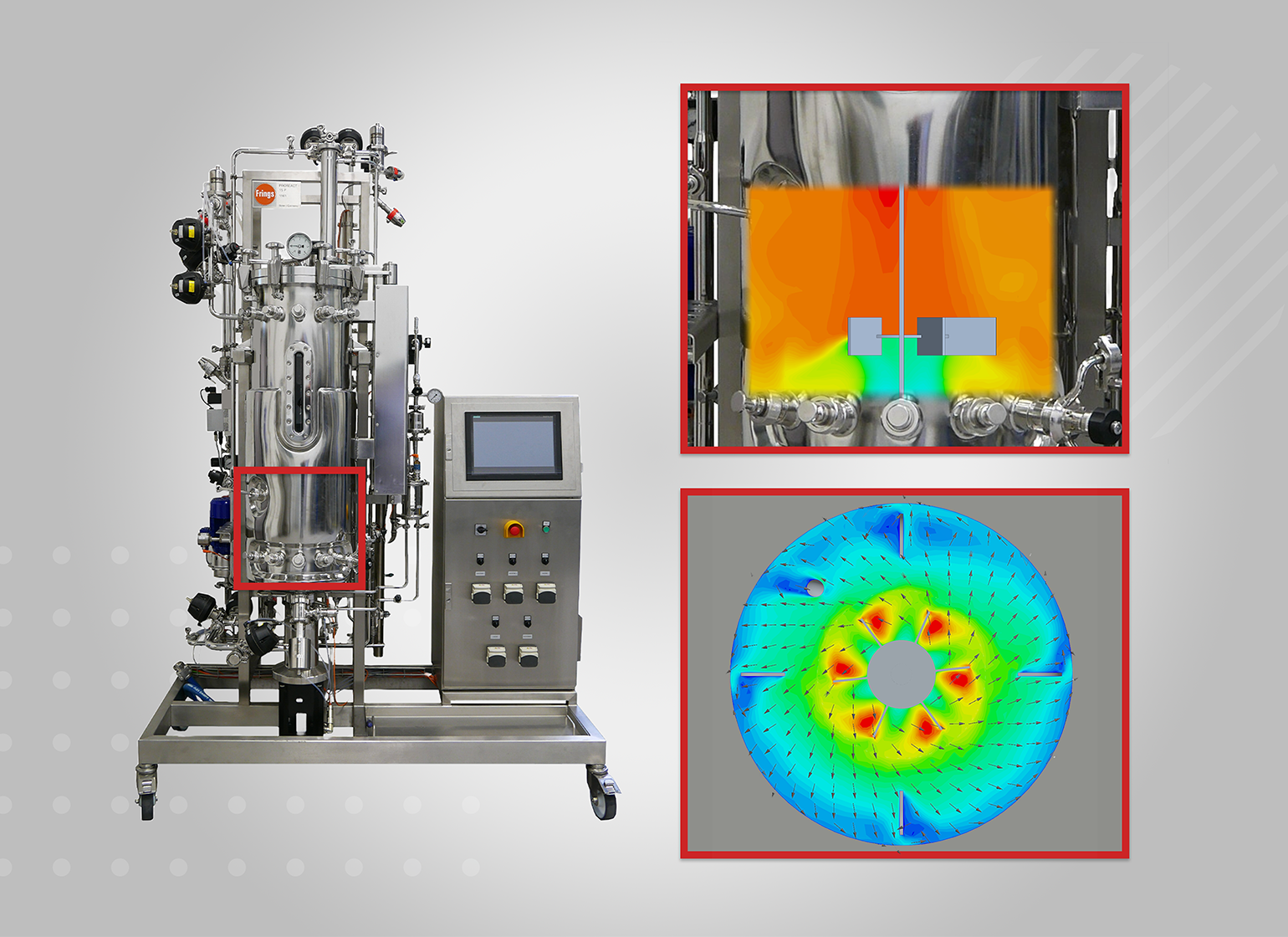

Utilizing CFD in Scale-Up: Computational Fluid Dynamics (CFD) plays a crucial role in addressing this challenge. CFD is a powerful tool that allows for detailed simulation of fluid flows, which is essential in fermentation processes. Through CFD, one can model the conservation equations for mass, momentum, and enthalpy, alongside factors like turbulence, viscosity, mass and heat transfer, and phase interactions. But the question remains: How does one effectively use CFD to facilitate scale-up in precision fermentation?

Steps in CFD-Assisted Scale-Up:

-

Understanding the Process: The first step involves a thorough understanding of the fermentation process at a laboratory scale. This includes knowing the key variables and how they interact within the system.

-

Developing the Model: Using CFD, a detailed model of the fermentation process is developed. This model is based on the laboratory scale but is adaptable to larger scales.

-

Simulating Scale-Up: The model is then used to simulate the scale-up process. This simulation includes adjustments to the size of the reactors and the operational conditions to reflect an industrial-scale setup.

-

Analyzing Results: The CFD model provides detailed insights into how the process variables will behave when scaled up. This includes understanding changes in temperature, concentration gradients, shear rates, and other critical factors.

-

Optimization: Based on the simulation results, the process can be tweaked and optimized. This step is crucial to ensure that the scaled-up process is as efficient and effective as the smaller version.

-

Predictive Capability: A key benefit of using CFD in scale-up is its predictive capability. It allows for the identification of potential issues before they occur in the actual industrial setup, saving time and resources.

Conclusion: CFD is an invaluable tool in the scale-up process of precision fermentation. It allows for detailed simulations that can predict how a process will behave at a larger scale, enabling optimizations and adjustments to be made beforehand. This approach ensures that the efficiency and precision of small-scale processes are retained when transitioning to an industrial scale, a crucial aspect for success in the field of biotechnology.